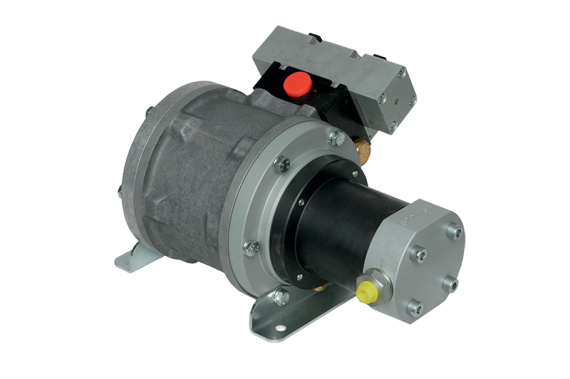

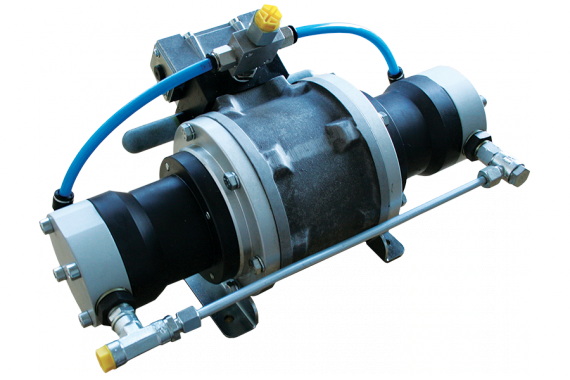

Olmec Air-Air booster offers a wide range of products that combines simple principles of operation with rugged construction suitable for the most demanding industrial applications.

An alternative to the purchase of a dedicated high pressure compressor, Olmec Air-Air booster are compact, require no electrical or mechanical drive connections, are powered by the same air that they amplify, and can be mounted in any position.

Key Features

-

Long seal life and easy maintenance

-

No heat, flame or spark risk.

-

Wide range of models and accessories available

-

No air inlet lubrication required the elimination of oily discharge.

-

Output pressure and flow infinitely variable.

-

Wide range of standard and custom systems .

-

Control of maximum pressure by pressure regulators.

Olmec Air-Air booster is an air pump as a function of inlet pressure allows to generate the operating cycle and multiply the output pressure. The pressure is generated using a differential piston. The low pressure air applied to the area of the large piston on the inlet side generates high pressure air on the small area of the piston on the output side. The continuous motion (pumping) is obtained through the use of two pilot valves that alternately opens and closes a series of internal passages that allow the reciprocating motion (also at great speed) of the pistons.

The type of seals used allows the section to operate without lubrication in the air inlet line.

The ratio of the areas between the pistons of low and high pressure is called “multiplication ratio” and represents the number after the model in all items. This ratio and the inlet pressure available determine the maximum output pressure of the Air-Air booster.

The Air-Air booster will automatically stop “stall” at its maximum output pressure at this stage there is no air consumption or heat generation. In the moment in which it generates a pressure drop within the high pressure circuit theAir-Air booster resumes its pumping to restore the desired pressure until the new condition of “stall”.

Double-acting models are available that offer higher performance in terms of pressure, flow rate and efficiency.

Tested a range of different sizes is available to meet the varied application where high pressure air is required.

Italiano

Italiano  English

English