In modern industry the precision of machining, the quality of the product, staff and plant safety, as well as quick clamping and release of the pieces being machined, are essential factors in the company’s productivity and competitiveness.

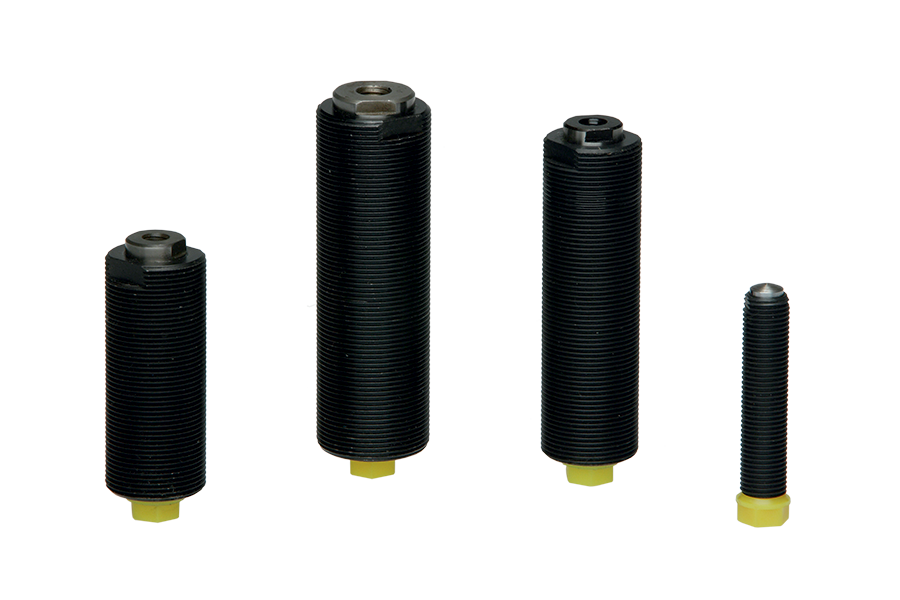

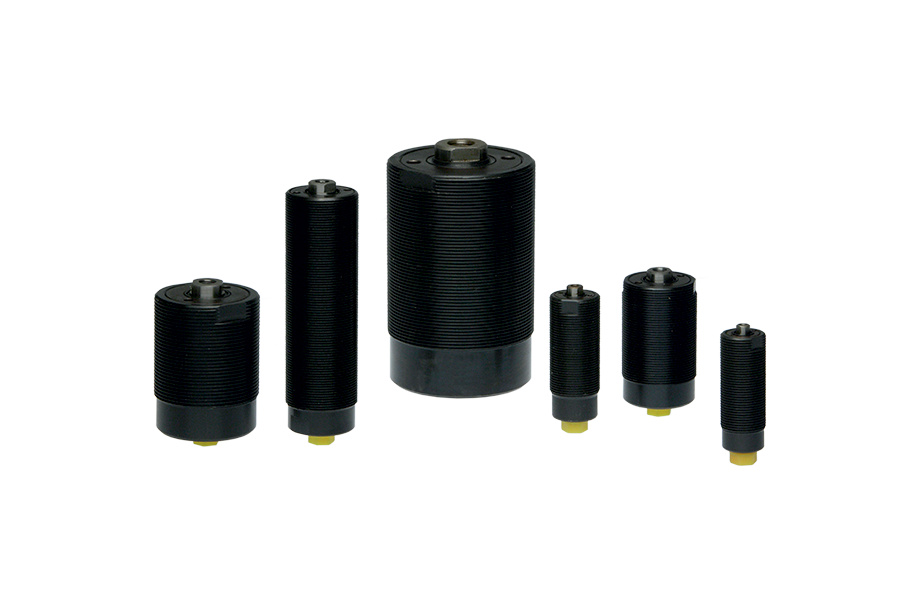

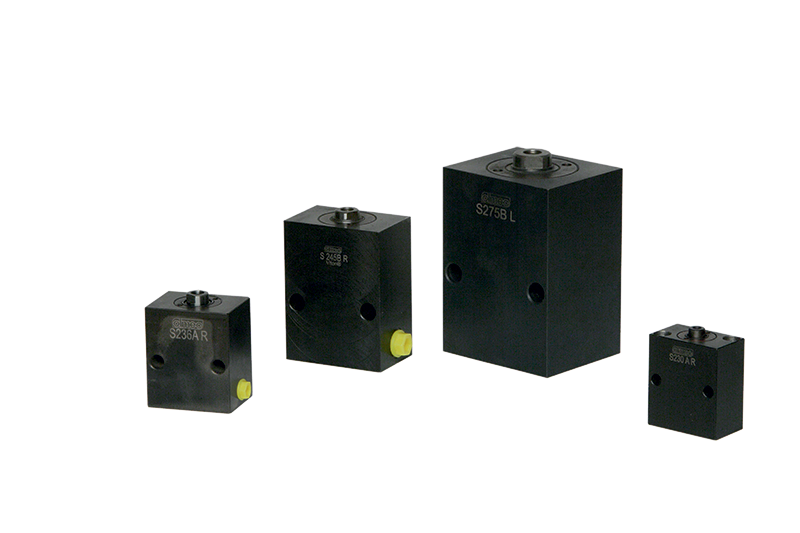

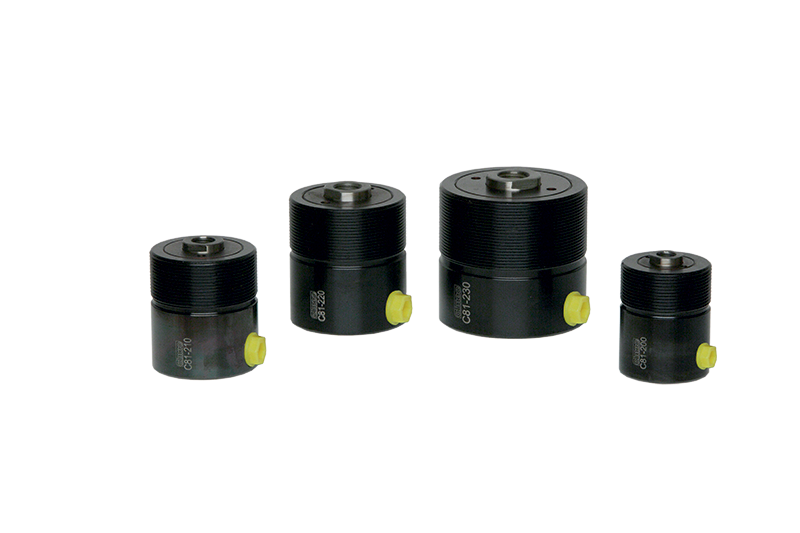

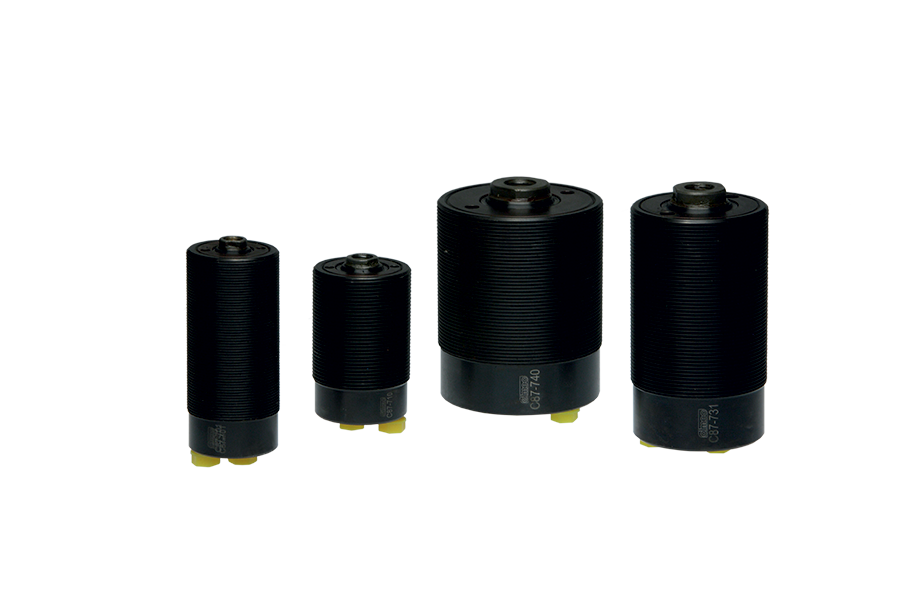

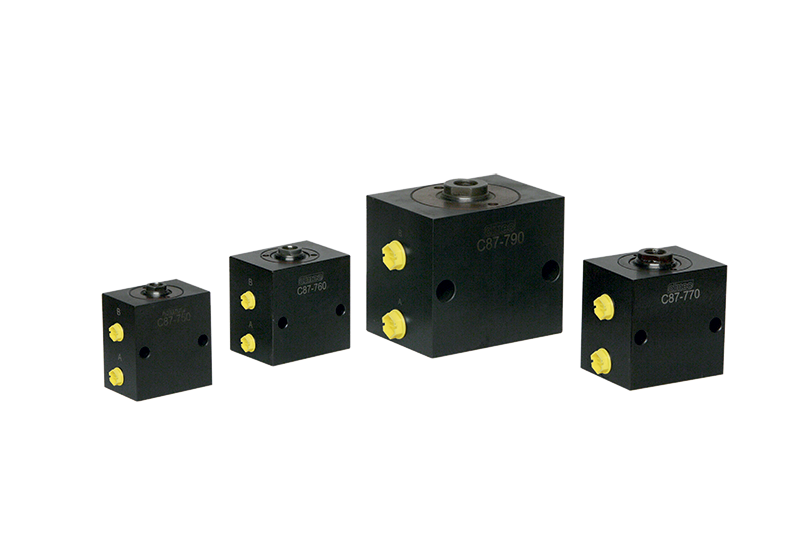

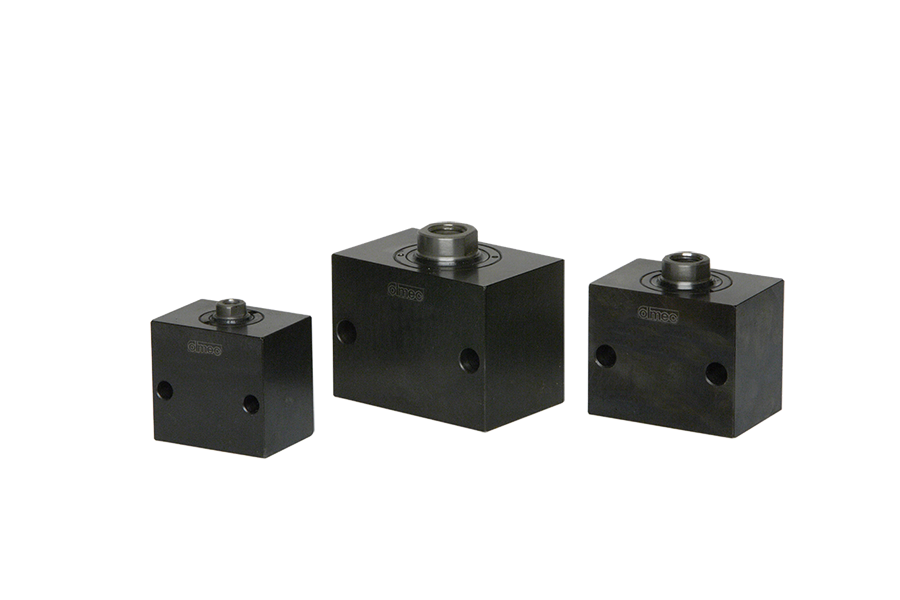

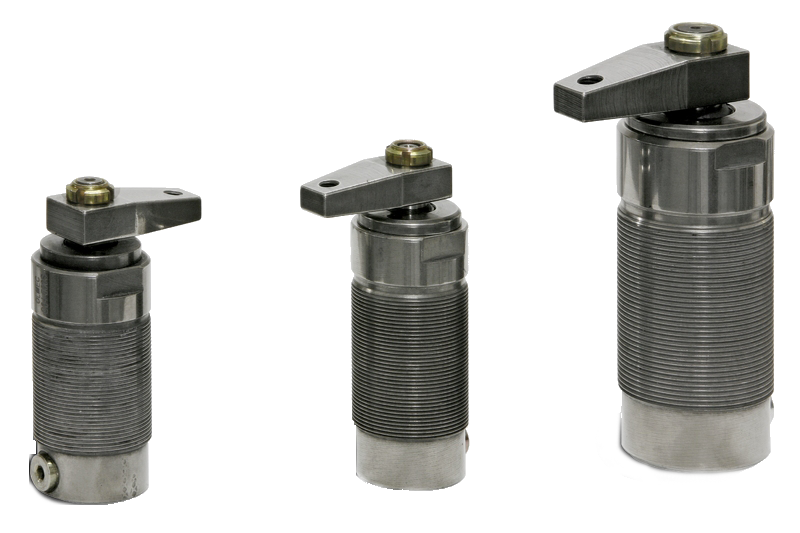

Thanks to their compactness and efficiency, OLMEC high pressure clamping systems significantly reduce times. Constructed using heat-treated titred steel, with low-friction bronze guides, they are assembled with seals of various types such as lled Te on, Polyurethane and O-rings. The maximum temperature of the pressurized uid must not exceed 60°C; if higher temperatures are envisaged, specify this on order so that the cylinders can be tted with suitable seals.

In order to ensure that the cylinders give satisfactory service users are advised to bear in mind a few fundamental rules:

- oil temperature 0°C + 40°C;

- ambient temperature +5°C + 40°C;

- hydraulic fluid viscosity 3°E / 50°C – ISO 32 / 46.

For design of an optimum piece of clamping equipment, a number of key points must be analysed carefully:

- number of pieces to be machined and production frequency;

- type of machine tool used and the machining times required;

- type of cylinder to be used in relation to the clamping forces required (see comparative table below)

In the design phase, ensure that most of the cutting forces generated by the tool are absorbed by the equipment and not by the clamping cylinders; this will reduce the costs necessary to clamp the pieces.

Italiano

Italiano  English

English